Rotary Valves

Rotary valves, also known as feeders, airlocks, rotary airlocks/feeders, star valves, seal valves, spider valves, metering valves, vane feeders, etc., are critical components in industrial processes that handle dry bulk materials. These versatile devices can function as a feeder, an airlock, or both, depending on the specific application. They serve to regulate the flow of materials, ensuring consistent and controlled transfer between different stages of a process or system. Delta Ducon offers a range of high-performance rotary valves designed to meet the demanding needs of various industries. Our Extreme, HD, and SHD Rotary Valves are engineered for superior durability, reliability, and efficiency, even in the harshest operating conditions. They are constructed with robust materials and advanced engineering to provide extended service life and minimal maintenance requirements.

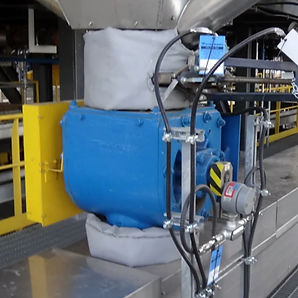

Extreme Rotary Valve

PERMA/flo Extreme Rotary Valve For abrasive, hot and hard to handle materials (Featuring a fully field adjustable and replaceable Cast P-33 High Nickel Chrome Alloy "550 BHN+" Rotor & Wear Shoe)(6" to 24")

Type “HD” Rotary Valve

The Type “HD” HD rotary valves fill a gap in the market between the typical industry standards of heavy duty and our PERMA/flo Extreme Rotary Valves. Designed for moderately abrasive materials and temperatures 300 F. (8” & 12”)

Type “SHD” Rotary Valve

The Type “SHD” Heavy Duty Rotary Valve is a general purpose industrial valve, featuring a direct to housing seal, fabricated rotors in various configurations and a cast iron housing Round & Square Configuration, (6” to 26”)

The Better Baghouse Valve

Filling a niche in the market between typical heavy-duty standards and our PERMA/flo Extreme Rotary Valves. They are suitable for moderately abrasive materials and can handle temperatures up to 300 F. Available in 8" and 12" sizes, these valves offer a superior alternative for baghouse filters and ESP’s.

Feeder Rebuild Program

Delta Ducon's PERMA/flo “XT & XL” Rotary Valves offer long-lasting durability and high quality, outlasting competitors by up to five times. Our MRO-based rebuild program restores these valves to like-new condition, ensuring reduced downtime and extended life. Contact us for your rotary valve needs.